Products

We sell - Bortolinkemo (PALLETIZER) - Omega Paking

| Country of origin | Italy |

| Corporate name | Omega Paking |

| Country | / Peru |

| Languages | English, Spanish, Italiano |

-

Product Details

1. PRE-LAYER: LAYER FORMATION ZONE THAT ALLOWS TO ELIMINATE DOWNTIME FROM THE MACHINE CYCLE: WHILE THE COMPLETE LAYER IS DEPOSITED ON THE PALLET, THE NEXT LAYER IS MOLDED IN THE DEDICATED AREA, WITHOUT WAITING FOR RETURN OF THE TRANSFER SYSTEM.

2. MULTIPLE INLET: A SOLUTION THAT ALLOWS 2 OR 3 ROWS OF PRODUCTS TO ENTER THE MACHINE AT THE SAME TIME.

3. AUTOMATIC PALLET UNLOADING: THE FULL PALLET CAN BE AUTOMATICALLY DRIVEN IN AREAS PROPERLY EQUIPPED TO BE TAKEN WITH FORKLIFT TRUCKS OR THE FULL PALLET IT CAN BE DRIVEN AUTOMATICALLY IN AREAS PROPERLY EQUIPPED TO BE TAKEN WITH FORKLIFT TRUCKS OR TO FEED MACHINES THAT CARRY OUT OTHER MACHINING SUCH AS FOR EXAMPLE BANDED WITH EXTENSIBLE FILM.

4. EMPTY PALLET STORAGE: UNIT THAT ALLOWS TO INCREASE THE AUTONOMY OF THE MACHINE NOTABLY: IT ALLOWS TO STORE 10-15 EMPTY PALLETS THAT ARE AUTOMATICALLY EXTRACTED TO BE DRIVEN TO THE PALLETING AREA OF A MEDIUM-CARRIED CADDY CONVEYOR. -

Technical information

-

Company Information

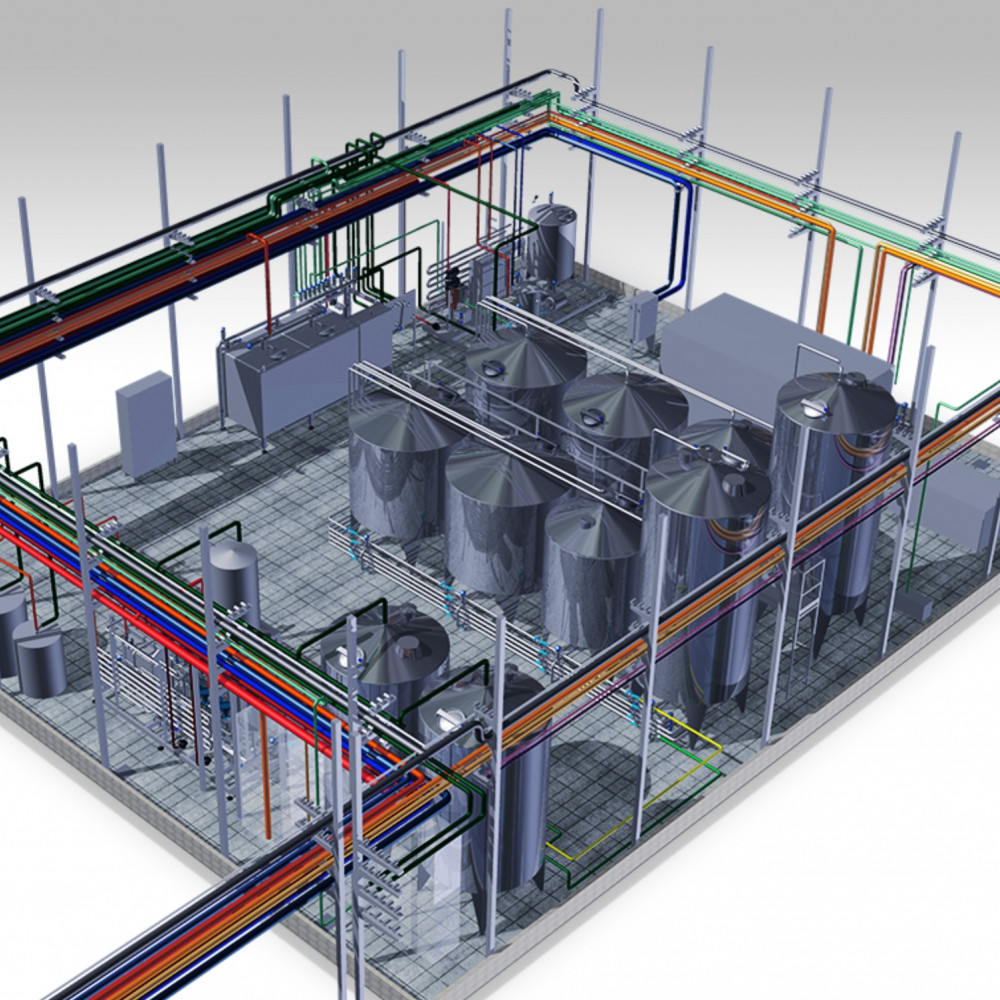

We are an engineering company with more than 50 years of

experience of its partners in the design, sale and installation of

lines and equipment for bottling, labeling and packaging.

We are allies and we sell the best machines of the most

renowned Italian manufacturers that have more than 230

years of experience.

We help clients to find solutions for their projects.

Our company has an Operations Department for

predictive, preventive and corrective maintenance with

regional technicians with many years of experience.

Located in Panama, Colombia, mexico y peru and , we can

provide installation, start-up and training services to

our clients.